New demands for modern production

Nowadays, in modern manufacturing production, higher requirements for precision and efficiency have driven more demand for

Automation; Especially for quality inspection and control processes, the application of automated solutions can replace manual labor and complete more time-consuming and labor-intensive work.

In order to help manufacturers meet the demand for automated quality testing, API has been leading and developing flexible automation solutions that meet the requirements of the times since its establishment.

Therefore, the 9D LiDAR based on OFCI optical frequency domain interferometry measurement technology emerged. With its ultra-high measurement accuracy, extraordinary measurement efficiency, and automated non-contact measurement methods, it has become an outstanding solution that transcends the times in the field of large-sized precision measurement.

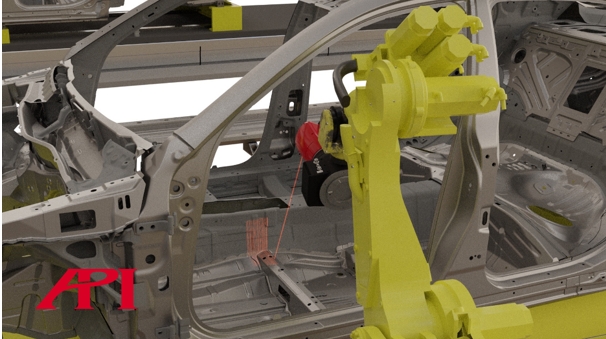

Figure 1: API 9D LiDAR (9D LADAR)

API 9D LiDAR

The API 9D LiDAR adopts Optical Frequency Domain Interferometry (OFCI) technology, which is suitable for non-contact and accurate measurement of workpieces or target objects in various environments and complex working conditions such as workshops, laboratories, and fields. It has micrometer level measurement accuracy and extraordinary measurement efficiency, and can quickly measure the size of workpieces and capture surface point cloud data.

When working, the 9D LiDAR generates broad-spectrum optical interference, detects signals, and collects measurement data. Its sensitivity is more than 100 times higher than that of conventional LiDAR, providing higher measurement accuracy and better measurement efficiency. Moreover, it is not easily affected by external environments during measurement, effectively avoiding the significant influence of material reflectivity on conventional LiDAR measurement equipment Limited range of incidence angle and susceptibility to environmental noise.

API 9D LiDAR has been proven to be an excellent solution for large-scale non-contact precision measurement through numerous international key cooperation projects.

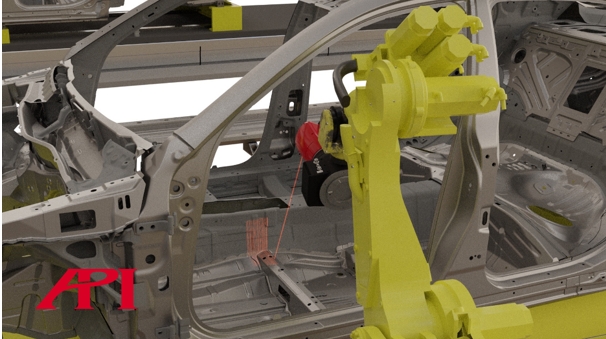

Figure 2: Application of API 9D LiDAR in Near Line Measurement of Automobile Production Line

9D Lidar Automation Measurement System

On the basis of the single machine application of 9D LiDAR, API has developed a series of component products that can achieve measurement automation, forming an automated measurement system that perfectly integrates into the construction of

Smart Factory automation system, further realizing the automation of non-contact detection of large workpieces, and providing support for the measurement and detection process of smart factories.

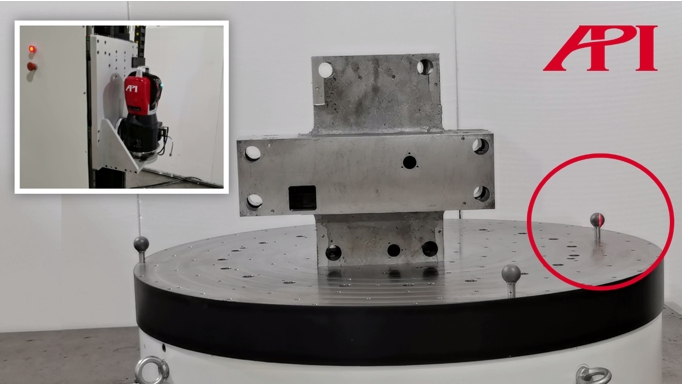

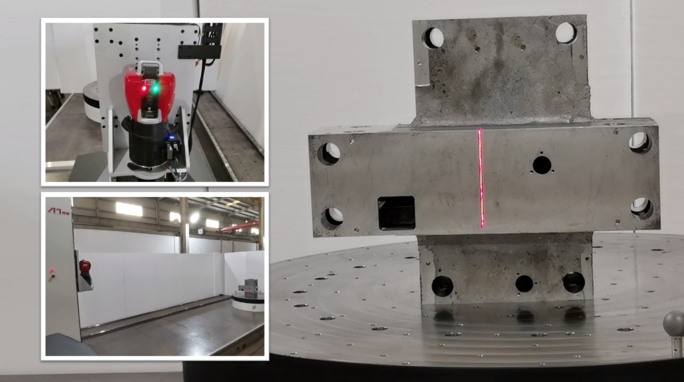

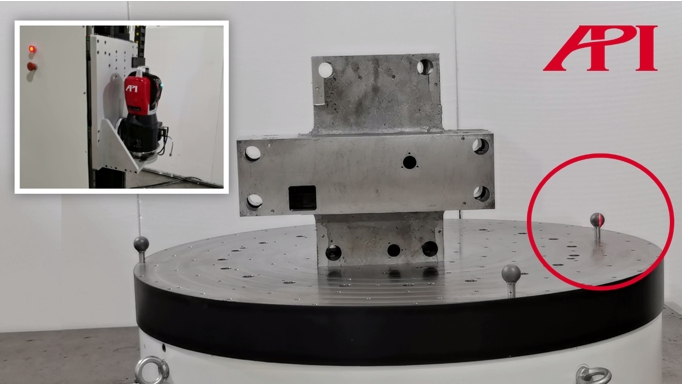

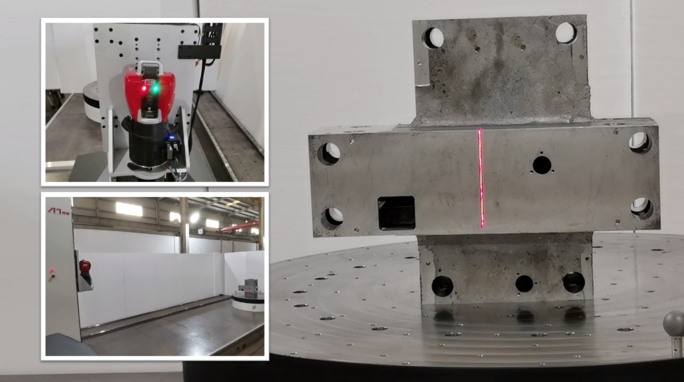

Figure 3: API 9D LiDAR automated measurement system with column and turntable coordination

Based on the usage needs of customers in different fields, API provides you with two working forms of laser radar+column+turntable automated non-contact measurement system:

① Automated measurement system with tool ball assisted automatic station transfer

In this automated measurement system, the 9D LiDAR is integrated on the base of a movable column that can be lifted and lowered, and scans and measures the workpiece to be measured on the turntable (see Figure 3).

When measuring, the 9D LiDAR first scans the pre-set tool ball (see Figure 4), unifies the coordinate system, and then performs precise scanning measurement on the overall or local characteristics of the workpiece A surface (see Figure 5); After the A-side operation is completed, the turntable automatically rotates to the B-side position, and the 9D LiDAR scans the tool ball again to achieve automatic station rotation. After that, the B-side of the workpiece is automatically scanned and measured; And so on, until the scanning operation on all sides of the workpiece is completed.

Figure 4: 9D LADAR scanning tool ball

Figure 5: 9D LADAR scanning workpiece

② An automated measurement system without the need for tool balls to assist in station transfer

The system structure is similar to the above system. The 9D LiDAR is integrated into a lifting column base, and the workpiece is placed on a turntable; Differently, high-precision gratings and circular grating coders are integrated into the column and turntable respectively, which can automatically provide accurate readings of the Z-axis and fourth axis (turntable) position or angle for the system without the need for tool ball turntables, achieving system performance.

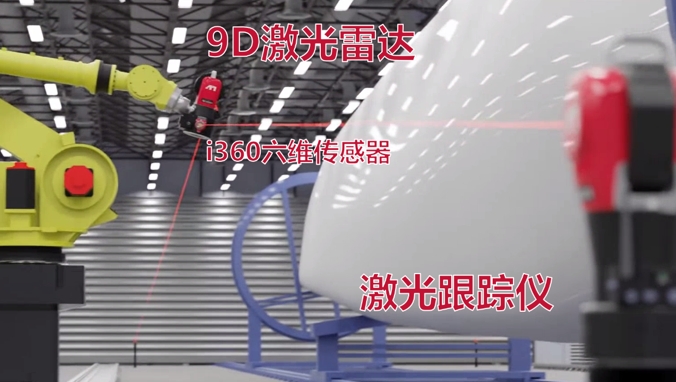

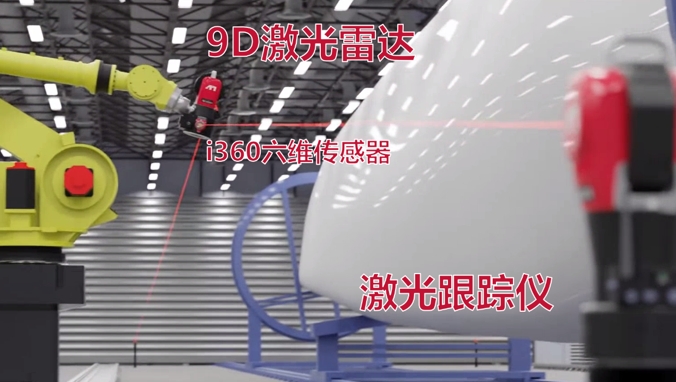

Figure 6: 9D LiDAR measurement system for global positioning of Laser Tracker in large-scale wind turbine blade measurement operation

A 9D LiDAR measurement system for global positioning of laser trackers

In addition to the automated measurement system based on columns and turntables mentioned above, the 9D LiDAR can also form a larger range of automated measurement systems or networks with the Radian series laser trackers.

In this system, the Radian laser tracker tracks the i360 six dimensional sensor integrated on the 9D LiDAR with extreme high precision in real-time, achieving six dimensional measurements (X, Y, Z, yaw angle, pitch angle, rolling construction), and providing real-time global positioning for the 9D LiDAR; On the basis of real-time positioning provided by the laser tracker, the 9D LiDAR performs scanning and measurement operations for target workpieces (see Figure 6).

This measurement method can also be applied to multi device networking measurement, thereby achieving accurate measurement of aircraft fuselage components, large wind turbine blades, etc.

Figure 7: API Company Headquarters Building

About API

The American Precision Engineering Corporation (API) was founded in 1987 and is headquartered in Rockwell City, Maryland, USA. Since its establishment, API Company has been committed to the research and production of precision measuring instruments and high-performance sensors in the field of mechanical manufacturing. Its products have been widely used in advanced manufacturing fields in the United States and countries around the world, and it is in a leading position in high-precision standards for coordinate measurement and machine tool performance testing. API Company has an experienced and capable team of engineers who continuously develop advanced and innovative products to meet the rapidly developing industrial technology needs. API companies are active participants and key technology partners in many projects of the US federal government, businesses, and scientific research. The achievements made so far have earned it a high reputation in the field of international precision measurement.